Overview

A simple TMR mixer, designed to last and to accomplish its task efficiently

Our new range of TMR pull type mixer has been designed to offer you a sober and efficient machine.

Down to the smallest detail, this pull type mixer aims for excellence.

3 models are available, going from 150 to 1500 cubic feet (4,2 m3 à 42.7 m3)

A tub and augers for an optimal mix

The various elements of the tub habe been assembled to offer an exceptionnal mix quality. The width of the floor, the angle of the walls and the inner tips are forming an ideal whole to ensure an homogeneous mix. Whether it is used for shredding bales or silage, give your animals a high-quality preparation.

The augers and their configuration in the tub are an important part of your mixer. Made of 3/4” thick 44W Canadian steel and with a stainless steel base, your augers are there to last. They are positionned to facilitate the exchange of foodstuff between the back and the front of the mixer and contribute to an efficien unloading of the tub.

The tub can also be doubled with 24 inch stainless steel liner for increased durability.

A perfect and long-lasting unloading

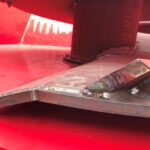

To ensure a perfect unloading, our vertical TMR mixer is equiped with a front centered door that is wide and high – hydraulically actuated – and a flat conveyor.

This 8′ flat conveyor (2,40m) allows a dual discharge. Moreover, its hydraulic system allows to offset it by 10 inches both side in order to discharge the food nearest to the animals.

And for durability? The conveyor base is made of stainless steel, as well as the chain.

A heavy duty frame and high performance wheels

The entire tub and conveyor structure are laying on a new reinforced tubular frame. Its single axle offers both stability and maneuverability.

The high-performance wheels are installed slightly inside the chassis and the conveyor discharge limit, which prevents you from driving on and compacting the ration you just handed out!

A smart weighing system

Equipped with a 4(6)-point weighing system, placed between the tub and the chassis, and a scale indicator that can be positioned on both sides of the viewing platform.

Details that make the difference

Several other elements have been designed to simplify your daily life: the ladder and viewing platform accessible from both sides, the windows to see the unloading process or the high LED lights… you will appreciate the ingenuity of our TMR mixer!