Overview

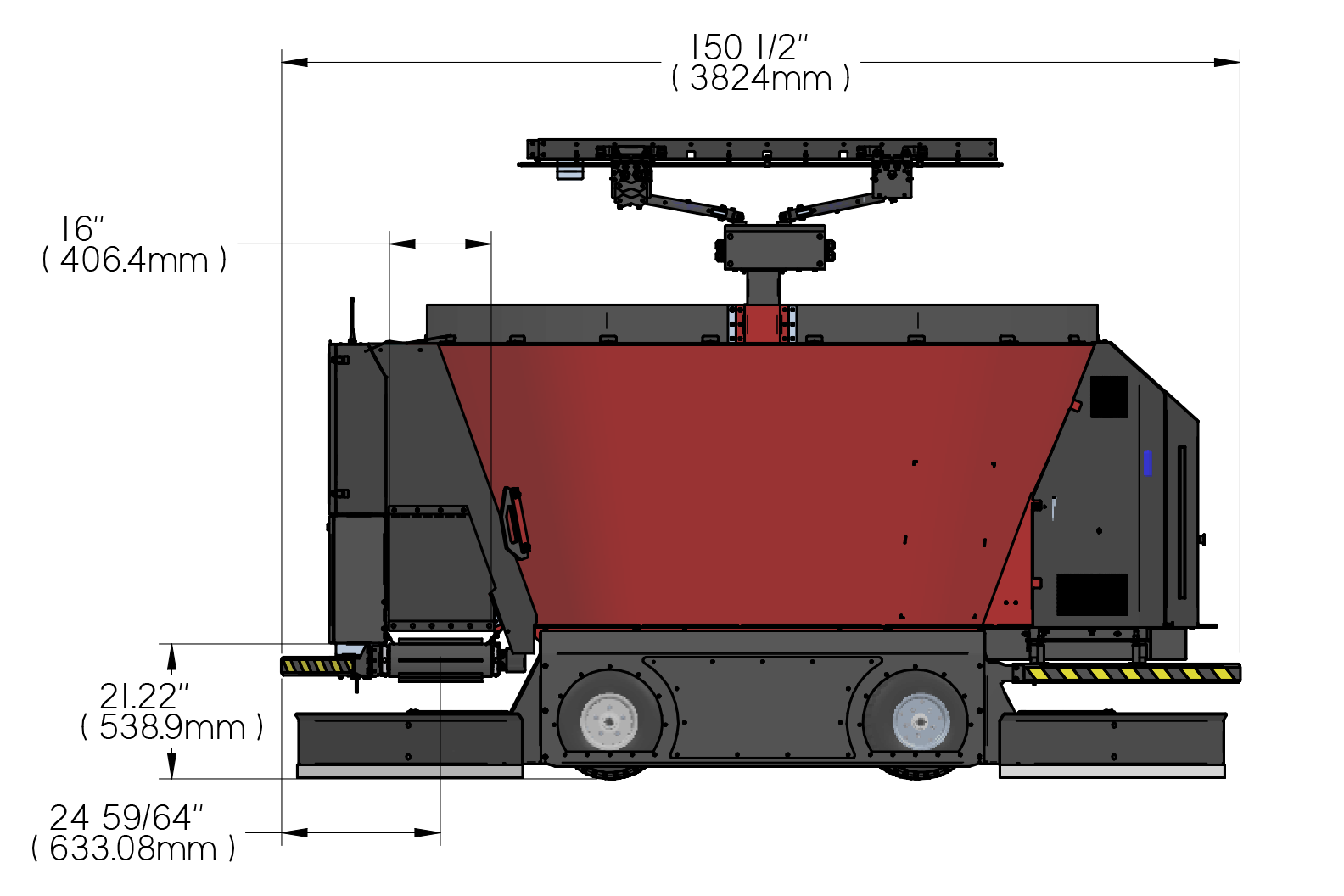

The ROVER is a completely autonomous feeding robot of 120 cu.ft. (3.4m3).

24/7 – You can count on your ROVER!

Fast and efficient, this feeding robot also pushes food back.

The ROVER will therefore allow you to manage your feeding in an automated way for your different groups of animals, even when feeding several times a day! The advantage of the feeding robot is to feed animals with a fresh and adapted recipe more frequently. This food management aims to optimize herd health and productivity – while reducing associated labour.

- 2 wear-resistant (Hardox) augers that can mix dry hay*

- Stainless steel liner in the tub, for greater durability

- Power supply via an conductor rail (240 or 380 V) that also guides the robot

- Four-wheel steering driven by hydraulic power

- 2-sided discharge conveyor

- Variable forward and discharge speed

- An integrated management software for your parks and recipes: up to 16 departures, 16 recipes and 32 ingredients

- A 2-years-warranty (parts and labour) as an option

*strong and dry fibrous Hay, quantity recommended – between 1 and 2 kg /cow /day.